How to Make a Fabric Formed Concrete Fire Table

This is a fun project that we completed during a recent training while exploring the use of vinyl upholstery fabric as a forming material. To quickly create the dramatic transition from a flat table surface to the trough holder, the trainees used a standard shop vac to hold the forms shape while casting the fiber reinforced concrete mix.

Project Difficulty

One: Forming

Heavy vinyl upholstery fabric is stretched taut over a foam riser and stapled to the underside of a 3/4″ melamine sheet to create the form base.

Learn MoreTwo: Vacuum Hookup

A shop vac is attached to the form base during casting to provide suction that pulls the vinyl fabric into graceful curves around the rigid foam risers.

Learn MoreThree: Spraying and Backing

A 3/4″ layer of CHENG’s D-FRC Casting Mix is sprayed into the base of the mold while the vacuum is running before a thin coat is sprayed onto the walls.

Learn MoreFour: Demolding

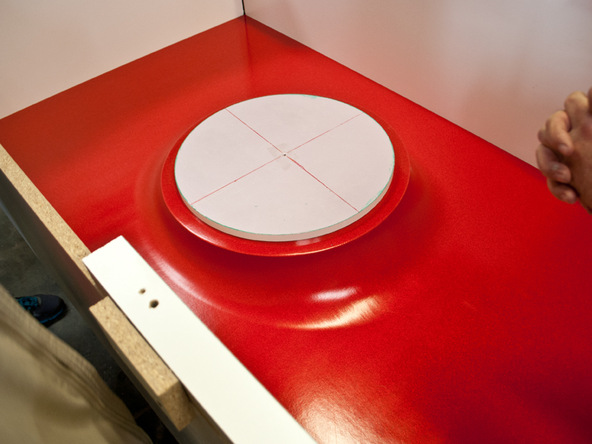

After the piece has cured for 12-24 hours, it can be removed from the formwork. Before demolding, the project is ground flat on the bottom edge.

Learn MoreFive: Finished Fire Table

Sealing your project will keep it looking great for years to come and prevent damage from harsh repeated freezing and thawing.

Learn MoreSix: Fire Table Variation

In a subsequent training we decided to create a smaller fire feature with lower side walls to reduce the time we spent laying up the higher walls.

Learn More