Fabric Formed Concrete Fire Table

TWO: VACUUM HOOKUP

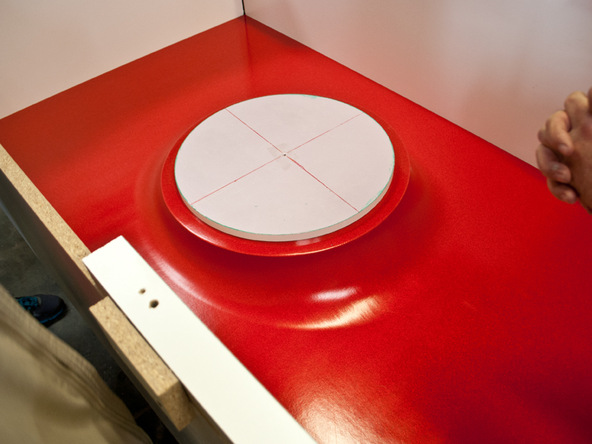

After the fabric is stretched over the central disc, it is sucked down with a shop vac, creating a smooth transition down to the burner.

What You’ll Need

- Saw Horses

- 3/4″ Drywall Screws

- Gasket Rubber

- Cordless Drill

- Duct Tape

- CS Unitec Vacuum Cleaner or Similiar

Step 1 – Air Hole

Step 2 – Vacuum Hookup

Previous: Forming

Heavy vinyl upholstery fabric is stretched taut over a foam riser and stapled to the underside of a 3/4″ melamine sheet to create the form base.

Next: Spraying and Backing

A 3/4″ layer of CHENG’s D-FRC Casting Mix is sprayed into the base of the mold while the vacuum is running before a thin coat is sprayed onto the walls.