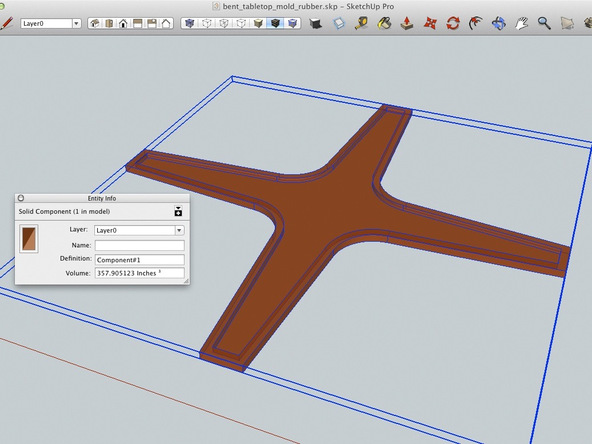

Bent Concrete Side Table

TWO: MIX RUBBER

Polytek 75-60 Polyurethane Mold Rubber provided the ideal flexibility for this project. The 75-60 was stiff enough to hold our desired shape without kinking at the curves while a softer mold rubber would have bellied or sagged at the curve points. Work quickly when mixing polyurethane mold rubber in order to avoid having the material setup before pouring.

What You’ll Need

Step 1 – Calculate Rubber Quantity

Step 2 – Mixing Rubber

Step 3 – Add Part A to Part B

Step 4 – Second Mix

Step 5 – Dry Gas Blanket and Cleanup

Previous: Make Mold

This project begins with a 3/4″ thick template made of melamine coated particle board which will be encased in polyurethane mold rubber to create a flexible mold.

Next: Cast Rubber Mold

Polyurethane mold rubber behaves like glue and will stick to most materials, so make sure that all surfaces are protected with Pol-Ease Mold Release.