Bent Concrete Side Table

THREE: CAST RUBBER MOLD

Polyurethane mold rubber behaves like glue and will stick to most materials, so make sure that all surfaces are protected with Pol-Ease Mold Release or plastic drop cloths.

What You’ll Need

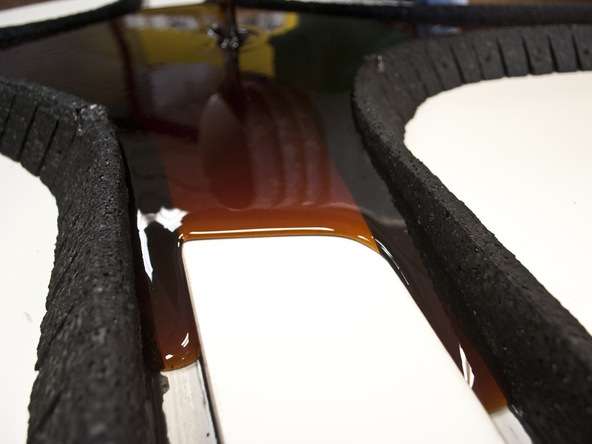

Step 1 – Pouring Rubber

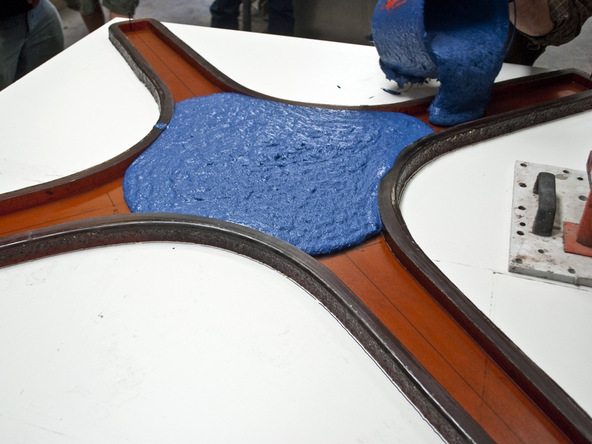

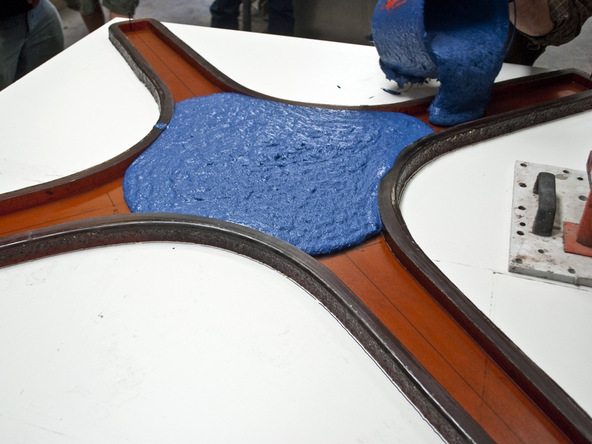

Step 2 – Fill Form Completely

Step 3 – Knock Down Air Bubbles

Step 4 – Cure Time

Step 5 – Demold

Previous: Mix Rubber

Polytek 75-60 Polyurethane Mold Rubber provided ideal flexibility for this project. Work quickly when mixing polyurethane mold rubber to avoid…

Next: Casting Concrete

To successfully cast this table you need to bend the concrete when it’s at the optimal “plastic” state. If you attempt to bend the concrete too early and…