Round Tabletop and Base

FOUR: TABLETOP FORMING

Video Overview

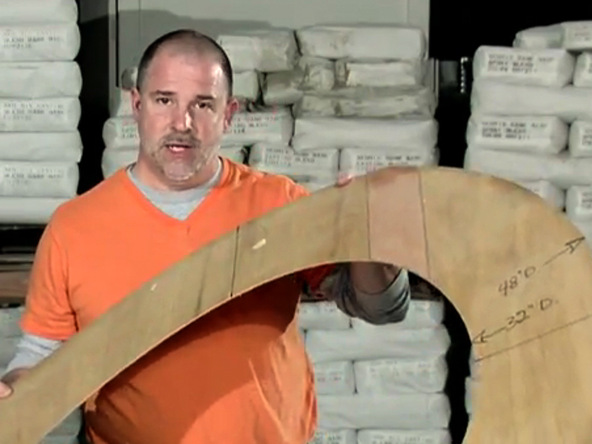

See how to create a mold for a 48-inch-diameter tabletop. First, a template is traced onto a sheet of melamine. Then, a curved form system is attached to the melamine with spray adhesive. Next a wall liner is attached to the forms to ensure a smooth edge. Finally, a knockout for an umbrella hole is created with a PVC pipe. With the form complete, the table is now ready for casting

What You’ll Need

- 100% Door and Window Silicone Caulk

- CHENG Corner and Seam-Shaping Tools

- Caulking Gun

- CHENG Pro-Form Curved Wall Forms

- CHENG Pro-Form Wall Liners

- 3/4″ Melamine

- 3M Super 77 Spray Adhesive

- Umbrella Knockout (PVC pipe, foam, clear tape, drywall screw, fender washer)

Step 1 – Work from a Template

Step 2 – Curved Form Walls

Step 3 – Complete the Form

Previous: Table Base Casting

Glass fiber scrim and fiber reinforced concrete backer mix is used to “stitch” the two halves of the table base form while the concrete is still pliable.

Next: Tabletop Casting

A flowable fiber reinforced concrete mix is initially sprayed into the form before a stiffer backing mix is placed as structural reinforcement.