Bent Concrete Side Table

FOUR: CASTING CONCRETE

As the saying goes “timing is everything”. To successfully cast this table you need to bend the concrete when it’s at the optimal “plastic” state. If you attempt to bend the concrete too early it’ll slump down the form into a pile of mess and if you wait too long it’ll crack at the curved points.

Step 1 – Prepare Casting Table

Step 2 – Mix Activator and Pigment

Step 3 – Add Fiber-Reinforced Concrete Mix

Step 4 – Consistency for Casting

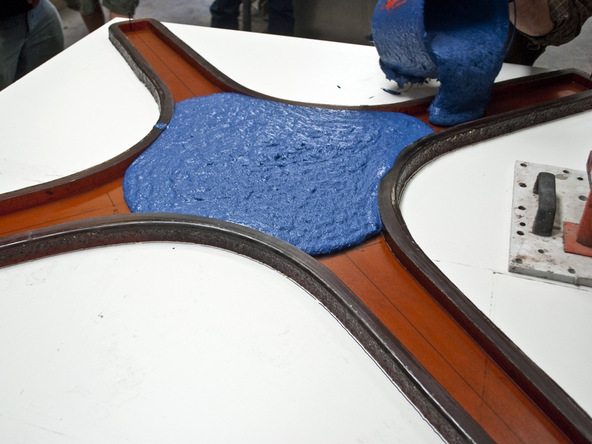

Step 5 – Pour Concrete

Step 6 – Bend

Step 7 – Bend and Cure

Previous: Cast Rubber Mold

Polyurethane mold rubber behaves like glue and will stick to most materials, so make sure that all surfaces are protected with Pol-Ease Mold Release.

Next: Demolding

Wait 24 hours before attempting to demold this project. The legs will continue to be delicate until the concrete has reached full strength in seven days.